Proper Planning for Industrial Facility Layout

Proper Planning for Industrial Facility Layout

- Newest Blog

The design of an industrial facility goes well beyond architectural skill; it is a strategic exercise in efficiency, safety, and foresight. Let’s look at why meticulous planning is paramount in industrial facility layout design and how the Team at Daedalus Co. is able to provide these crucial skills for your next project.

An industrial facility of almost any use is built for the sole purpose of creating, packaging, storing, and/or distributing tangible products. The design team you choose to partner with should have an in depth understanding of the requirements specifically relating to these areas.

When the Daedalus team is brought into a project of this type, we begin by talking with the project owner about their specific goals.

- In-Depth Analysis of Operational Requirements: We begin with a thorough analysis of the client’s operations. Our main objective is to understand the nature of the work, the machinery involved, and the daily processes in use currently, or being planned. This includes identifying the type of manufacturing, storage needs, and any special requirements such as temperature control or hazardous material handling.

- Long-Term Business Objectives: What are the long-term goals for this project? Is the project an expansion to existing production lines? Will the client require additional space(s) to support the process? Or is the project a brand-new production operation? Understanding these objectives is crucial for creating a layout that is flexible and scalable.

- Budget Constraints and Financial Planning: A key aspect of understanding our client’s needs is to work within the allocated budget. This involves making cost-effective design choices without compromising on quality, safety, or efficiency.

- Collaborative Understanding: We engage in meetings and updates with various stakeholders from the client’s side, including management, production staff, and maintenance staff as required. This collaborative approach ensures that the design aligns with the practical day-to-day experiences and insights of those who will use the space.

- Site Analysis and Utilization: If we are contracted to develop an existing site, we conduct a detailed site analysis to understand the limitations and possibilities. This includes assessing the geographical location, environmental factors, and existing infrastructure and utilities availability. This step is often overlooked, or minimized in scope as the value of this process is often not seen until later on in the project. Specifically, reviewing the available utilities such as electrical capacity, water, compressed air, natural gas, etc. and creating a detailed report can provide insight to the design team for equipment selection, or ultimately what prerequisite steps are required to bring more utility capacity into the project area(s). (See our article on the power of 3D scanning)

Going through these initial steps allows both the designer and the client to gain a full understanding of the facility so that a detailed plan of execution can be developed. This plan will be paramount in determining the project budget and full scope of work.

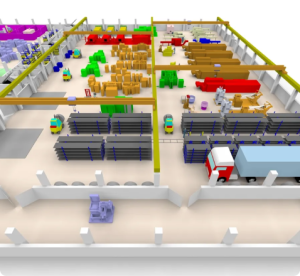

At Daedalus, we understand that the heart of a successful manufacturing facility lies in its efficiency and workflow optimization. When we collaborate with our clients, our primary focus is to streamline their production lines, both existing and new systems. This involves a meticulous arrangement of machinery, materials, and workstations to enhance operational flow and minimize unnecessary movements.

We prioritize optimal space utilization, ensuring every square foot of your facility serves a purpose. This includes strategically balancing operational areas with storage and office spaces for maximum efficiency.

Recognizing the importance of staff well-being, we integrate ergonomic designs into workstations. This approach not only boosts comfort but also enhances productivity by reducing fatigue and strain.

Embracing modern technology, we are able to incorporate automation solutions tailored to your operations. Whether it’s advanced robotics or efficient conveyance systems, these integrations are key to reducing manual labor and streamlining processes in the most effective ways possible.

Understanding that business needs evolve, we aim to create facility designs and process layouts with future adaptability in mind. Flexibility in layout design allows for easy reconfigurations or expansions as your business grows.

Safety and Regulatory Compliance

We place the utmost importance on safety and adherence to regulatory standards in our designs. Working closely with our clients, we ensure that every aspect of the facility layout is aligned with safety protocols and industry-specific regulations.

We integrate critical safety features, including clear access to emergency exits, adequate space around machinery for safe operation and maintenance, and proper ventilation systems as required. Our team stays abreast of the latest regulatory requirements, ensuring your facility not only meets but exceeds these standards.

Sustainability and Future-Proofing in Industrial Facility Layout Design

At Daedalus, our commitment to sustainability focuses on future-proofing your facility and process lines. We closely collaborate with our clients to select machinery and equipment that excel in energy efficiency, ensuring long-term operational cost savings and reduced environmental impact. Our designs are strategically planned to accommodate future technological advancements, maintaining relevance and efficiency in an ever-evolving industrial landscape.

Technology and Innovation in Industrial Facility Layout Design

At Daedalus, technology and innovation form the cornerstone of our approach to industrial facility and process layout design. We leverage state-of-the-art 3D design software, enabling us to provide a detailed visualization of the final project. This not only aids in precise planning but also allows our clients to envision the space before construction ever begins.

Our commitment extends to aiding in the selection of advanced machinery and equipment that promises high efficiency and longevity. We are constantly exploring emerging technologies in automation and robotics to enhance productivity and reduce manual labor.

We also assist with the integration of smart systems for real-time monitoring and management of the facility and individual processes, ensuring optimal performance and quick response to any operational needs. With Daedalus, your facility is not just built for today’s standards; it’s developed with an eye towards the future, helping you stay ahead of your competition.

At Daedalus, we don’t just design industrial facilities; we craft future-ready environments that help propel your business forward. With our expertise in efficiency, safety, maintenance, sustainability, and technological integration, we aim to ensure that your facility is more than a workspace—it’s a cornerstone of your success.

Are you ready to elevate your industrial facility with a design that blends innovation with practicality? Let’s start a conversation. Contact Daedalus today to explore how our tailored solutions can meet your unique operational needs and prepare you for the future. Your vision, coupled with our expertise, will pave the way for a thriving, dynamic facility.