The Power of 3D Scanning in Commercial and Industrial Spaces

The Power of 3D Scanning in Commercial and Industrial Spaces

- Newest Blog

Welcome to the ever-evolving world of facility design, where the traditional blueprint meets the digital age. At the heart of this transformation is 3D scanning – a technology that’s changing how we approach the design and redevelopment of commercial and industrial spaces.

Whether you’re planning to enhance your manufacturing process or considering an expansion, understanding the role of 3D scanning can be a game-changer. This technology isn’t just about sophisticated equipment; it’s about making your design process smarter, more accurate, and incredibly efficient. Let’s look at how 3D scanning is bringing a new perspective to facility design, making it easier to visualize, plan, and execute your ideas.

3D Scanning: A Game-Changing Technology for Facility and Space Design

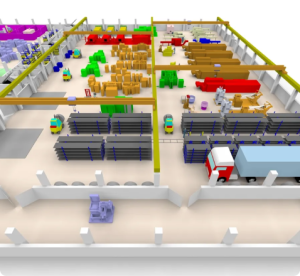

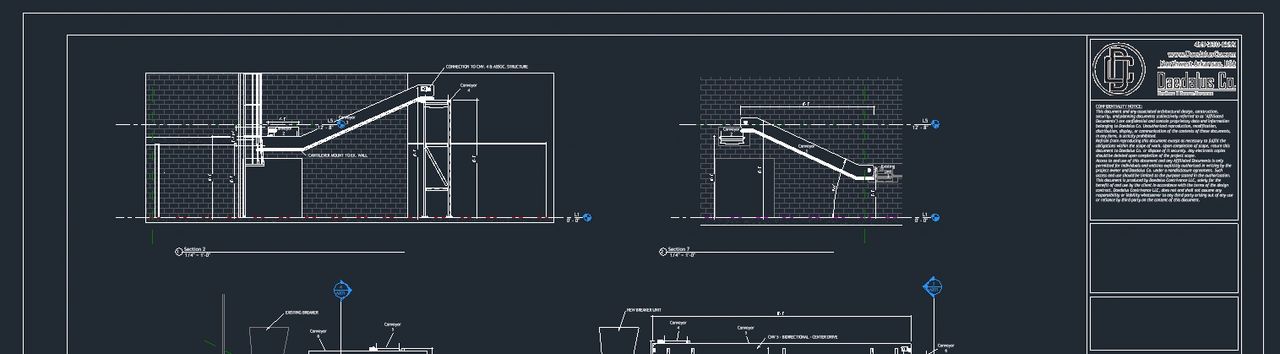

In the realm of facility design and expansion, 3D scanning is a transformative tool. The process starts with creating a ‘digital twin’ of your existing space – a virtual model that is the exact replica of your physical facility. This twin serves as a detailed reference point for every decision and change. Using the data captured during the 3D Scanning process, this digital twin is developed in powerful 3D design software such as Autodesk Revit or similar applications.

The creation of a digital twin through 3D scanning isn’t just beneficial; it’s a game-changer in facility management and design. This virtual replica does more than mirror physical spaces; it opens a world of insights and possibilities:

- Unmatched Precision for Design and Planning: By capturing every aspect of your facility with pinpoint accuracy, the digital twin removes uncertainty, allowing for precise and confident decision-making.

- Streamlined Problem-Solving: Visualize and tackle space-related challenges effectively. With the digital twin, you can test and refine solutions in a virtual environment before any physical changes are made.

- Cost and Time Efficiency: This approach significantly reduces the need for time-consuming and costly traditional surveys, accelerating the design process and minimizing disruptions to ongoing operations.

- Harmonious Integration of New and Old: Seamlessly blend new designs with existing structures. The digital twin ensures that expansions or modifications complement and enhance the current setup, maintaining operational flow and aesthetic integrity.

A digital twin is more than just a technological marvel; it’s your facility’s future in high definition, enabling smarter, more strategic, and sustainable decisions. In essence, a digital twin created through 3D scanning is more than just a model; it’s a dynamic tool that brings your facility’s potential into clearer focus, enabling smarter, more informed decisions.

3D scanning is revolutionizing the way we approach manufacturing process design in industrial settings.

By creating a detailed digital model of your facility, we can identify inefficiencies in your current layout and visualize improvements in real-time. This technology enables us to redesign your manufacturing process for optimal efficiency, reducing waste and increasing productivity. Whether it’s reorganizing workflow, optimizing space utilization, or integrating new machinery, 3D scanning provides a clear and accurate foundation for these critical decisions. The result? A streamlined, cost-effective, and future-ready manufacturing process tailored to your specific needs.

The transformative power of 3D scanning extends beyond industrial spaces this beneficial tool lends equally well into commercial realms.

For commercial facilities, this technology allows us to reimagine and optimize customer-facing areas and back-end operations alike. By creating a digital twin, we gain insights into customer flow, space utilization, and operational dynamics, leading to more informed design decisions.

In both commercial and industrial settings, the digital twin becomes a pivotal tool for enhancing the layout and function. It allows for the testing of various scenarios, ensuring that changes in design lead to tangible improvements in efficiency, customer experience, or production flow. This level of detailed planning and visualization was once a complex challenge, but with 3D scanning and digital twins, it becomes a streamlined, integrated process, offering a clear path to a more functional and successful facility design.

Facilitating Efficient Expansions and Renovations

In the realm of expanding and renovating commercial and industrial facilities, 3D scanning plays a pivotal role. By creating a comprehensive digital twin, we gain invaluable insights for both extending and upgrading existing spaces. This approach ensures that expansions integrate seamlessly, and renovations enhance functionality while respecting the facility’s original character. The precision of 3D scanning enables us to envision and implement changes that are in perfect harmony with your current layout, making the process of expanding or renovating not only more efficient and cost-effective but also in tune with the unique dynamics of your facility.

3D scanning is not just a tool for expansion; it’s equally transformative in renovating existing commercial and industrial spaces. When it comes to renovations, understanding the intricate details of the current facility is crucial. The digital twin generated from 3D scanning provides us with this detailed understanding, enabling us to identify potential issues like structural limitations or logistical challenges early in the design process. This foresight is invaluable, as it helps in planning renovations that are not only aesthetically pleasing but also aligned with the facility’s operational needs. The ability to simulate renovations in a virtual environment allows us to explore various design options, ensuring the final outcome is both practical and innovative, catering to the evolving demands of your business.

Overcoming Challenges

As an emerging technology, adopting 3D scanning into facility and spatial design comes with several challenges. At Daedalus, we have equipped ourselves to navigate these complexities. The foremost challenge is ensuring data accuracy. Without proper processes and best practices, the initial scan data can be faulty or inaccurate. Our team is trained to use and deploy these sophisticated scanners in nearly any environment and obtain accurate data consistently.

Data management is yet another challenge in the process workflow. The data generated by a 3D scanner can often be hundreds of gigabytes, and often times exceed a terabyte in size. When working with datasets of this size, the storage and access to these files requires a comprehensive data management solution. Daedalus has identified this particular challenge and has developed bespoke systems to handle this requirement. We employ advanced software systems, storage solutions with multiple redundancies, and technical expertise, ensuring that the data required to create the digital twin is accurate, safe, and organized.

Another challenge lies in effectively integrating these digital insights into practical design solutions. Our team excels in translating complex 3D data into actionable design plans, ensuring that the technology serves its ultimate purpose – to enhance and streamline your facility’s design and function.

Rest assured, the end product deliverables that you, the client, will receive are very manageable in size (less than 100mb, and often under 50mb), and can be navigated without the need for expensive software or Indepth training.

Looking ahead

As we look towards the future of facility design, 3D scanning stands out as a critical tool in shaping efficient, adaptable, and innovative spaces. At Daedalus, we’re committed to harnessing this technology to its fullest potential, helping our clients reimagine their commercial and industrial spaces. The integration of 3D scanning into our design process is more than a technological advancement; it’s a step towards smarter, more responsive, and sustainable facility design. As your partners in this journey, we’re excited to explore the possibilities that this technology holds for your facility, today and in the future.

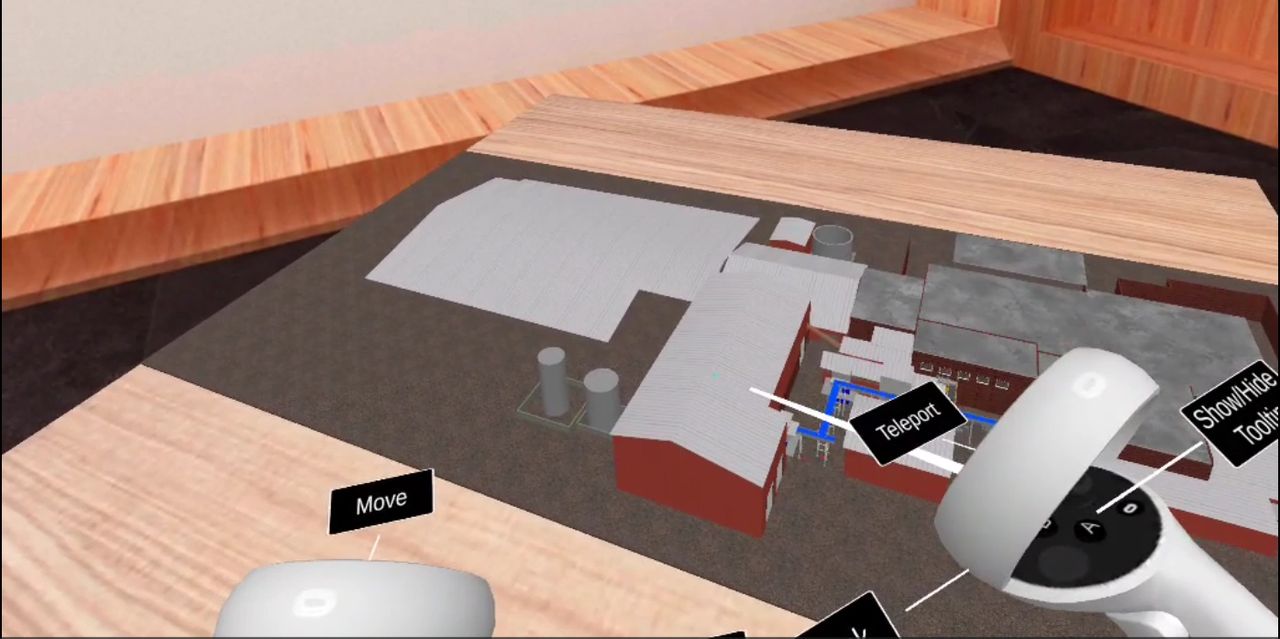

Special bonus! Ask us about our virtual reality/augmented reality integration to project design!

Share this post: